Bloggy Blog 17 - The Future is Lasers

As had been mentioned before, last year I invested in a laser cutter. How I got to the point of getting a laser cutter is an interesting tale of random coincidence. During the middling part of the pandemic, where Kayla was back teaching in school but I was still working from home, I did as I do and would go on very long walks over my lunch break. This gave me an opportunity to explore the streets and areas around our house.

One day, I was wandering around the area I like to refer to as "Olde Town Silicon Valley", an area that's all old 80s/90s office buildings that are either now abandoned, occupied by tech companies that nobody's ever heard of, or about to be plowed under and replaced with offices for Google/Facebook. As I was wandering, I saw a sign for "Maker Nexus" that I'd not seen before. Curious, I checked out their website as I finished my walk and they were a maker space that had very recently relocated. They did regular classes on the various big machines they had and one of those series of classes just happened to be for laser cutters.

Now, I'd vaguely wanted a laser cutter for some time. The CNC mill that I'd bought was supposed to scratch the itch of working with materials in a 2D fashion, because my chops for doing 3D printing were as yet under developed. However, the CNC mill - while an incredibly powerful machine - has a huge learning curve and requires a lot of nursing to get done right. I still haven't properly harnessed the power of this thing. A laser cutter, however, can be fed a vector file created in Illustrator (a program I'm very familiar with) and it'll cut that out of whatever material you want. (This is an over simplification, but the nuance is simple enough that I'll allow it).

Sign up for the laser cutter classes, I did, and it seemed to be every bit as easy and awesome as I'd made it out in my head. I didn't yet know what to do with this knowledge, but I cut a few test pieces and etched a few more. It was the random acrylic etching I made that wound up giving me a direction for laser cutting. I'd left the piece sitting next to my keyboard, which has fancy lights running around the outside edge. Kayla noticed that if you put the etched acrylic up next to the lights, it made the etched parts light up which the rest was still transparent. We were in the throes of wedding planning at the time, and we both pretty much thought the same thing: this would make dope-ass light up signs for some of the various stations. So, I set about designing a 3D printed, edge lit base that would fit a piece of etched acrylic, reserved some time for the maker space laser, and wound up churning out four or five of these signs.

They were super dope and, honestly, all the wedding crafts we did probably deserves its own post. The laser and 3D printers were really put through their paces.

As time plodded on, I went back to the office, and Maker Nexus started becoming busier as they picked up more members, reserving time for the laser, making sure all my stuff was perfect before going over, and driving out there to hopefully get my work done became a bit of a mental barrier (at the very least). So, I started spiraling the drain hard over buying a laser cutter to call my own.

My god did I spiral.

It was to the point where Kayla was getting annoyed and told me to just buy the damn thing. So I did. And, after some fun getting it out of the wooden shipping box it came in (think leg lamp in a Christmas story) and up into the house, I had my own laser which I could use whenever.

There's still a little bit of mental overhead in working out how to pull a project off, but I feel more productive with it than I ever did with the CNC mill or (until more recently) the 3D printer. Here's a sampling of some of the better projects I've pulled off.

House numbers that I have yet to finish and install...

A house numbers sign, made at the request of my in-laws. This one has been installed. (3mm acrylic, cemented together)

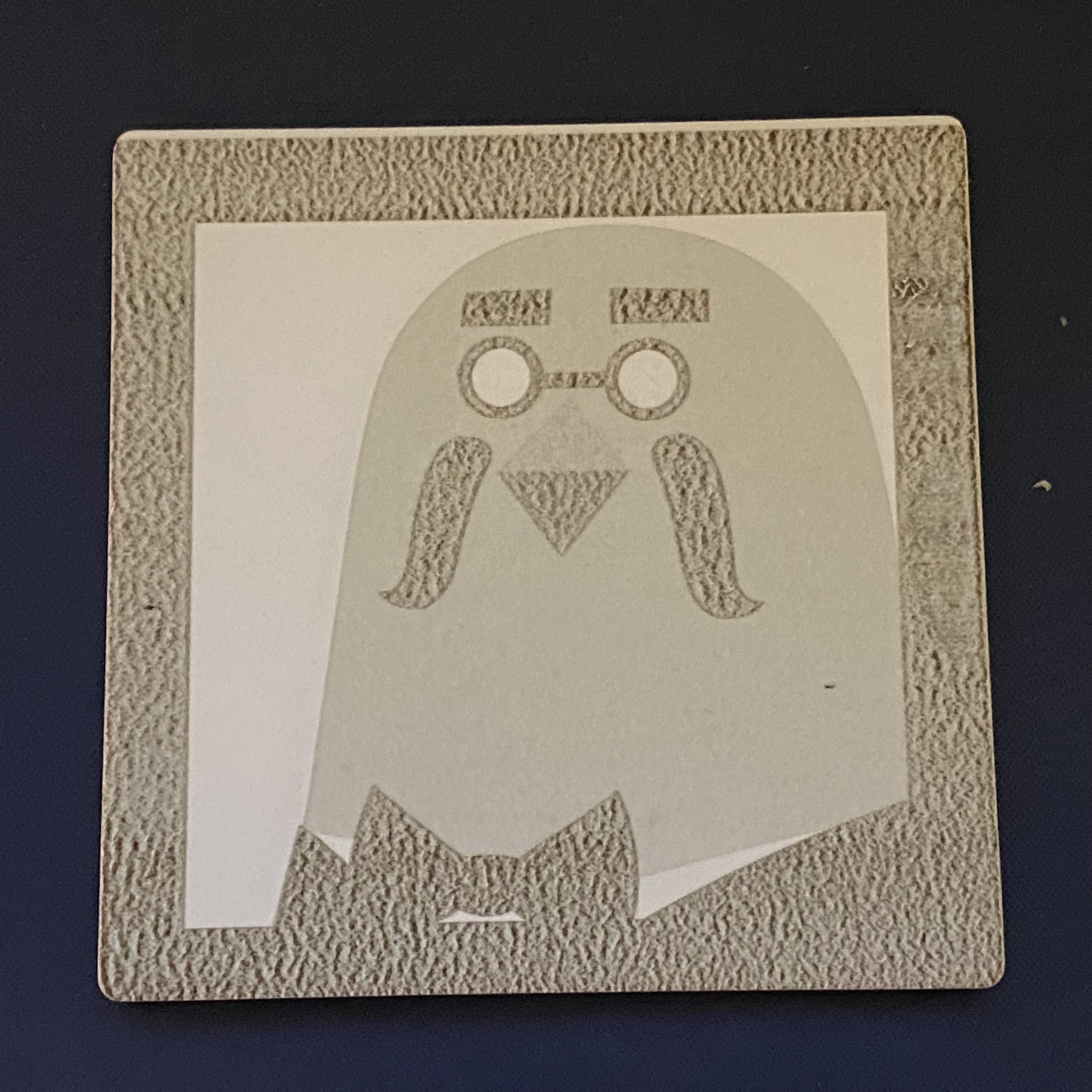

A coaster with the likeness of everybody's favorite coffee pigeon, Brewster (multi-pass etch on ceramic, not 100% successful).

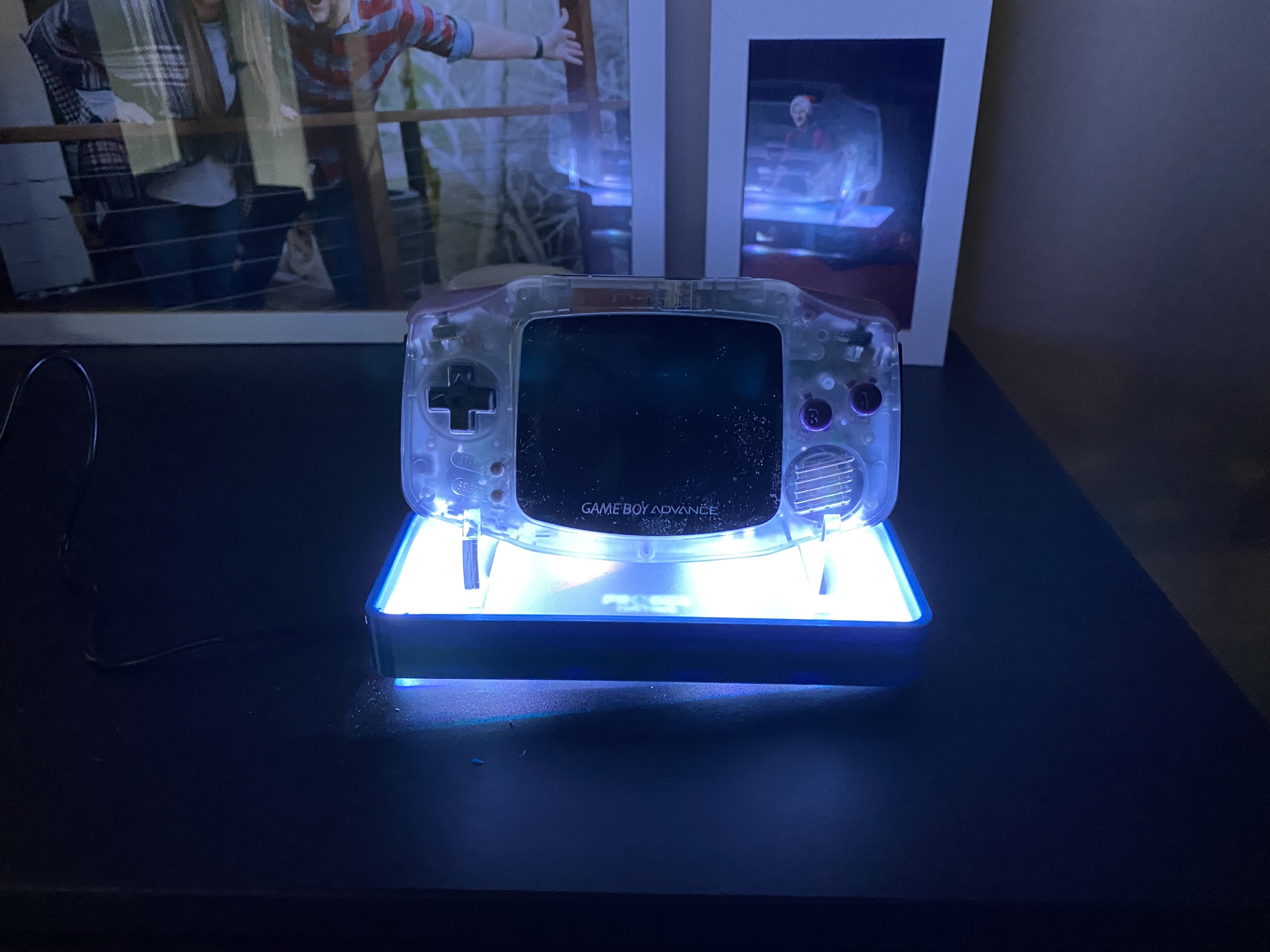

A GBA stand with lit 3D printed base. It's hard to make out, but my brother's GBA mods logo is etched on the acrylic.

A medal holder for all of these runs that I've shuffled through (multiple layers of 3mm birch ply, colored with alcohol markers).

As part of a random gifting thing that's done on Disney cruises, I made dozens of these keychains to give out to strangers.

What does the future have in store? Who knows, the sky's the limit. But, there is one thing I've saved for the end... the thing that's still a work in progress.

The one that's gonna show up on an electronics YouTube channel...